Making a table tennis or ping pong racket

The manufacture of table tennis rackets, also known as table tennis blades, depends on a process that includes several steps. Here is a general overview of how they are made:

1.- Selection of wood: The process begins with the selection of suitable materials. The board or blade is usually made of wood and can be made up of several plies (layers). The selection of wood types and their arrangement in the plywood determine the playing characteristics of the table tennis wood.

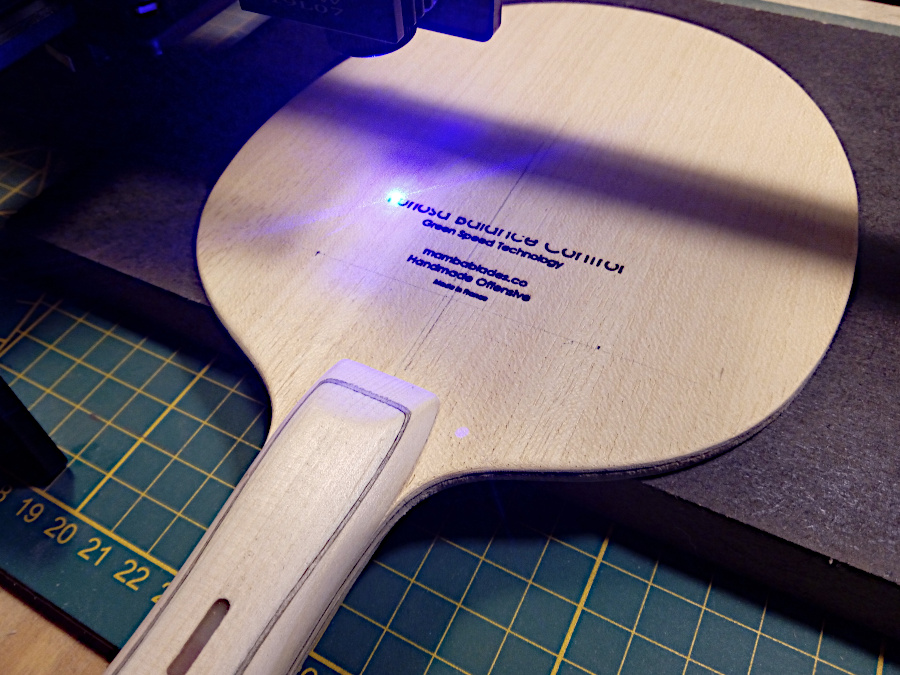

2.- Cutting the board: The board or blade is cut according to the shape and size desired for the racket. The cutting process may involve the use of computer-guided machines or traditional methods, depending on the manufacturer’s processes and technology.

3.- Handle construction: If the table tennis blade requires a handle, it is produced separately. Handles are generally made with materials such as ayous, rosewood, cork, spruce or composite materials. Then, we shape, sand and fix the handle to the blade, already cut, using a liquid adhesive.

4.- Application of rubbers: Two rubber sheets, also called coatings, are attached to the table tennis blade. They have two distinct sides: one for the forehand and one for the backhand. The rubbers are glued to the playing surface of the blade then cut to size.

5.- Cutting of the rubbers and finishing: after fixing the rubbers. Then the excess rubber material is cut away to create a clean, even playing surface. You can also smooth the edges of the blade and give them a neat finish. This ensures the comfort and safety of the player.

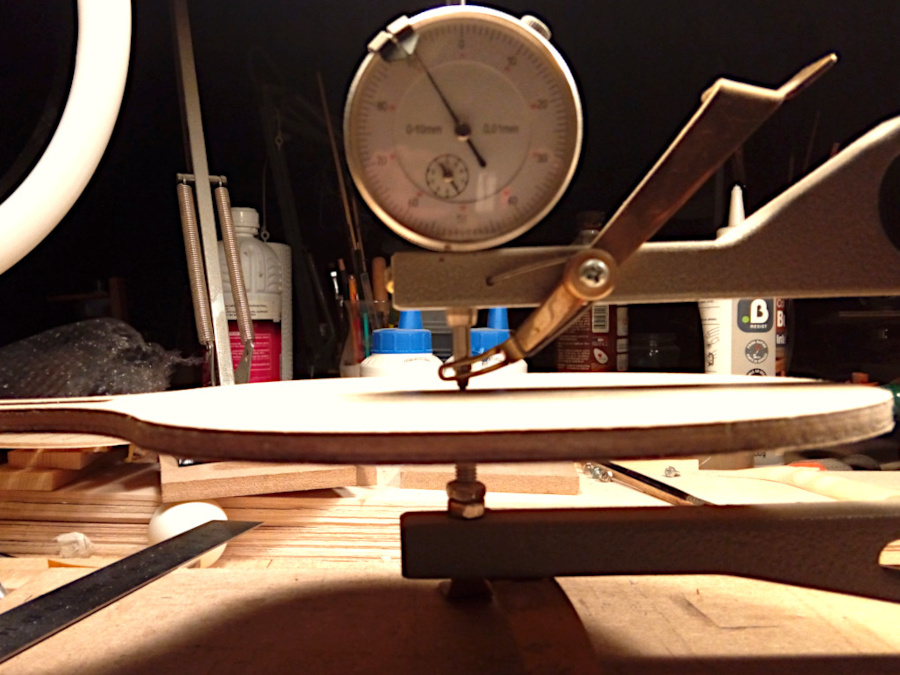

6.- Quality control: Once the racket is assembled, it undergoes quality checks to ensure that it meets the standards. This may include checking weight, balance and general racquet construction, rebound.

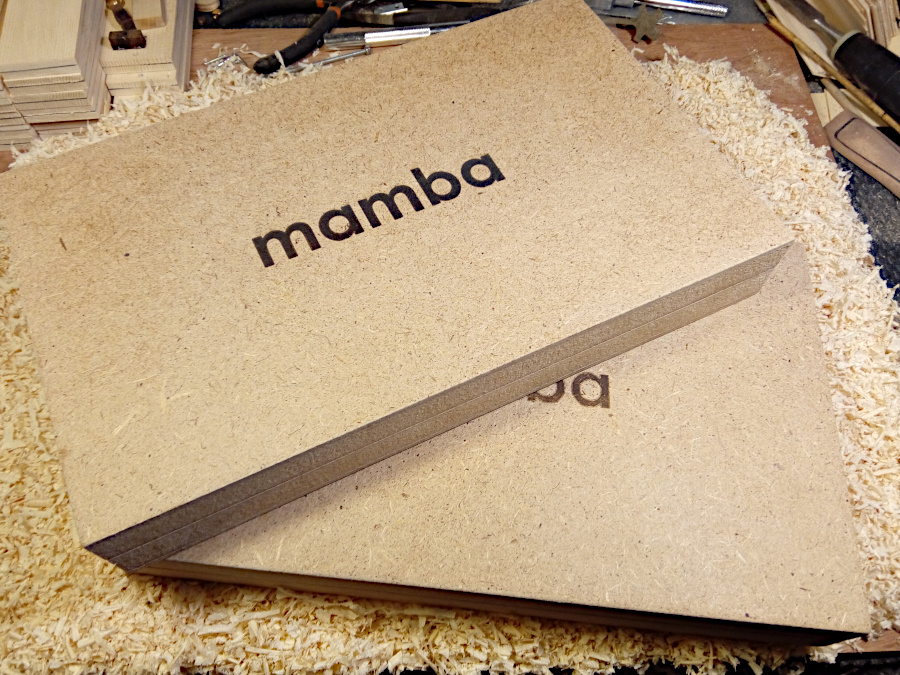

7.- Packing: Finally, we pack the table tennis racket. Additional accessories such as a case or protective cover are often added. It is prepared for distribution to retailers or customers.

It is important to note that the manufacturing process for table tennis rackets may vary slightly between different manufacturers and brands.

Additionally, some racquets may have additional features or technology built into their design. thus, there are rackets with natural reinforcement layers or specialized materials and systems. These can therefore influence the manufacturing process.