Manufacturing of Table Tennis Rackets

The manufacturing of table tennis rackets, also known as table tennis blades, follows a meticulous process that includes several essential steps. Here is a detailed overview of each phase of manufacturing:

Selection of Wood

The process begins with the choice of suitable materials. Then, the plank or blade of the racket is generally made of wood, often composed of several layers of wood (plies). The choice of wood, as well as the orientation of the layers, determines the characteristics of the racket, such as speed, control, and playing feel. Finally, the most commonly used woods are often ayous, balsa, limba, and maple.

Cutting the Plank

Once the wood is selected, it is cut to obtain the desired shape and size for the racket. This step can be done using automated machines or traditional methods, depending on the tools and strategy of each manufacturer.

Handle Construction

If the racket requires a handle, it is made separately. Handles are often made from materials such as ayous, rosewood, cork, or spruce, but some manufacturers also opt for composite materials. The handle is then shaped, sanded, and glued to the blade with liquid adhesive, thus forming the complete racket.

Application of Rubbers

A key step is to apply the rubber coatings. Two sheets of rubber (one for the forehand and one for the backhand) are cut to the size of the wood and firmly glued to the playing surface of the racket. The rubbers can vary in terms of thickness and texture to meet the specific needs of the player.

Cutting the Rubbers and Finishing

After fixing the rubbers, the excess rubber is cut off to obtain a perfectly uniform playing surface. The wood of the racket can also be smoothed, and the edges polished to offer optimal comfort to the user, while ensuring safety during use.

Quality Control

After assembly, the racket is subjected to rigorous quality control. This includes checking the weight, balance, stiffness, and overall construction quality. Each racket is tested to ensure it meets performance and safety standards.

Packaging

Finally, the racket is carefully packaged for distribution. It may come with additional accessories. For example it could be a protective cover, and is ready to be sent to retailers or directly to customers. This final process ensures that the racket arrives in perfect condition to the player.

It is important to note that while the manufacturing steps follow a standard process, each manufacturer can introduce variations according to specific technologies or materials used. Some high-end rackets include reinforced layers with materials such as carbon fiber or even natural composite materials, like flax fiber or hemp, to offer better stability, power, and responsiveness.

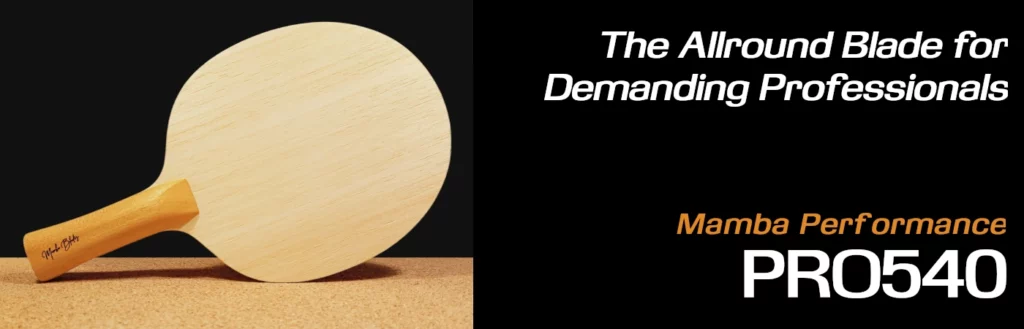

Featured image: Mamba Blades Image “How Table Tennis Rackets Are Made”